Transport is the single biggest source of CO2 emissions at global level. This is also true in Switzerland, where transport accounts for more than a third of total carbon emissions, ahead of industry and private households (each representing around 20%). To reduce the impact on the environment, Switzerland and other countries need to switch to zero carbon transport. Electric or hydrogen vehicles are particularly well-suited to this purpose, provided that the power is generated from renewable energy sources. Swiss companies, in particular, are finding solutions to these considerable challenges.

Switzerland is keenly aware of the problems caused by pollution and has outlined an electric mobility roadmap for achieving a 15% increase in new electric car registrations by 2022. These have increased considerably since 2018, reaching approximately 11% in 2019. Although Switzerland is not a major car manufacturing country, it produces innovative designs for small modular vehicles that are particularly suited to city driving. It is also actively involved in developing hydrogen powered transport, with some innovative solutions already in the pipeline, such as Stadler Rail’s FLIRT H2 train.

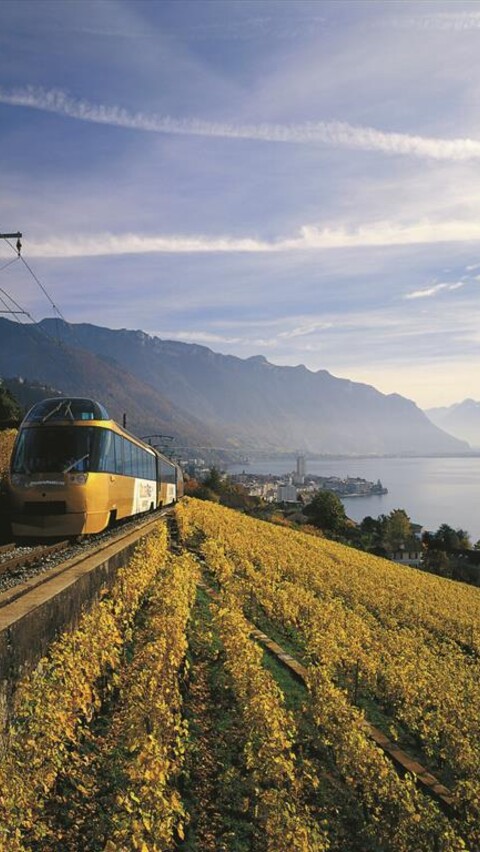

In the public transport sector, Switzerland has one of the highest rates of train use in the world. It also has first-class infrastructure and one of the world’s highest density rail networks, which is largely powered by renewable energy from hydroelectric plants. Switzerland has also been responsible for some important innovations in urban public transport, such as ABB and TOSA buses, which allows fast contactless charging at bus stops, and the e-buses produced by HESS.

Softcar

The first fully ecological car

Designed using plant-based plastic materials and advanced composites, and therefore fully recyclable, Softcar will be the world’s first totally eco-friendly car. Swiss-built, this ultra-light city car powered 100% by electricity and scheduled for mass production in assembly plants near major cities can be built with little investment, without compromising on safety or driving performance. The trail-blazing vehicle has fewer than 2,000 parts, as opposed to the 40,000 of today’s average car. The reduced number of components makes recycling easier, thereby conserving natural resources. The Softcar designers have come up with a car that reduces the carbon footprint from the moment it is produced, during use and right through to recycling at the end of its lifecycle. The development team drew inspiration from the concept of the ‘Swatch mobile’ city car conceived in the 1990s, while adding current technologies and the latest developments in components. The ultimate city car, this vehicle is the result of an exceedingly streamlined design that reduces its grey energy. Mass production began in 2023.

Designwerk

Electromobility and commercial vehicles: develop, drive, charge and store

Designwerk develops and manufactures electric lorries in small production runs, as well as fast portable chargers, megawatt battery-assisted rapid charging stations and modular high-voltage battery systems. The company is behind the first all-electric refuse collection vehicles on Swiss roads. It manufactures electric trucks with an unrivalled battery capacity of 1,000 kWh and a range of up to 630km. Its chargers are widely used by European carmakers. Modular traction batteries allow small and medium-sized carmakers to expand or shift their business into electric mobility. Since its creation in 2008, Designwerk has been promoting electric mobility through its innovative products and projects, making sustainable mobility more popular. The company has extensive expertise in the mobility sector, and focuses on special applications with complex technical requirements and the development of tailor-made solutions for its customers. Since 2021, the Volvo Group has held a stake in Designwerk. As of 2024, the latter has 220 employees at its sites in Winterthur, Switzerland where it has its head office, and in Lottstetten, Germany.

Leclanché

A New Era in the Marine Sector

Swiss company Leclanché, a leading provider of energy storage solutions, designs and manufactures battery systems for a wide range of infrastructure and vehicles around the world. These include ‘Ellen’, the world’s largest all-electric ferry, which has been shuttling between the Danish ports of Søby and Fynshav since 2019. The ferry is powered byLeclanché’s battery system, which provides zero carbon transportation with no fuel or exhaust smells on board. The battery system enables the ferry to travel 41 kilometres: seven times longer than any other e-ferry route. The Ellen can carry up to 200 people and around 40 vehicles. The e-ferry and its highly innovative battery system, which were partly developed in Switzerland, are helping to reduce the volume of diesel used on ferry routes.

Green Motion

Charging stations that make electric mobility more accessible

Green Motion, which became part of the Eaton Group in 2021, designs and produces turnkey charging stations for electric vehicles (EVs), whether for use at home or at public stations. It also offers a software platform for managing the related networks, including billing for the recharging. These two complementary but separable services give it two paths into the market. Its chargers, compatible with almost all EV plugs, are already installed in many countries, including China, India, Israel and the United States. In addition, the Swiss company is currently designing a charging station for electric aircraft, which is right on track for becoming widely accessible, as well as on-board chargers for the automotive industry.