From 13.04.25 – 13.10.25

Experience Switzerland’s inventive spirit in the Swiss Pavilion at the Expo 2025 in Osaka, Japan: The lightest ever built by Switzerland for a World Expo

The Swiss Pavilion

Find all practical information for your visit here.

Admission to the Swiss Pavilion

The Swiss Pavilion welcomes all Expo visitors with a valid Expo ticket. No reservation is required — simply join the queue at your convenience.

Hours

Open daily from 9 am – 9 pm.

Admission to the Heidi Café

The café operates independently from the pavilion with its own entrance and queue. Having visited the pavilion does not grant priority access to the café.

Hours

9:30 AM–7:30 PM: No booking (food served as of 10 AM).

8:20 PM–9:30 PM: Swiss Experience Set Menu (limited seating). Tickets are sold in front of the pavilion the same morning.

Café Menu*

Enjoy our selection of Swiss dishes infused with Japanese flavors for a unique fusion dining experience. Our menu celebrates both culinary traditions with thoughtfully crafted offerings. *Menu is subject to changes.

Advance booking

School visits require advance booking. Please contact protocol@swisspavilion.org to secure your group’s visit.

Hours

Same as general admission (9am–9pm).

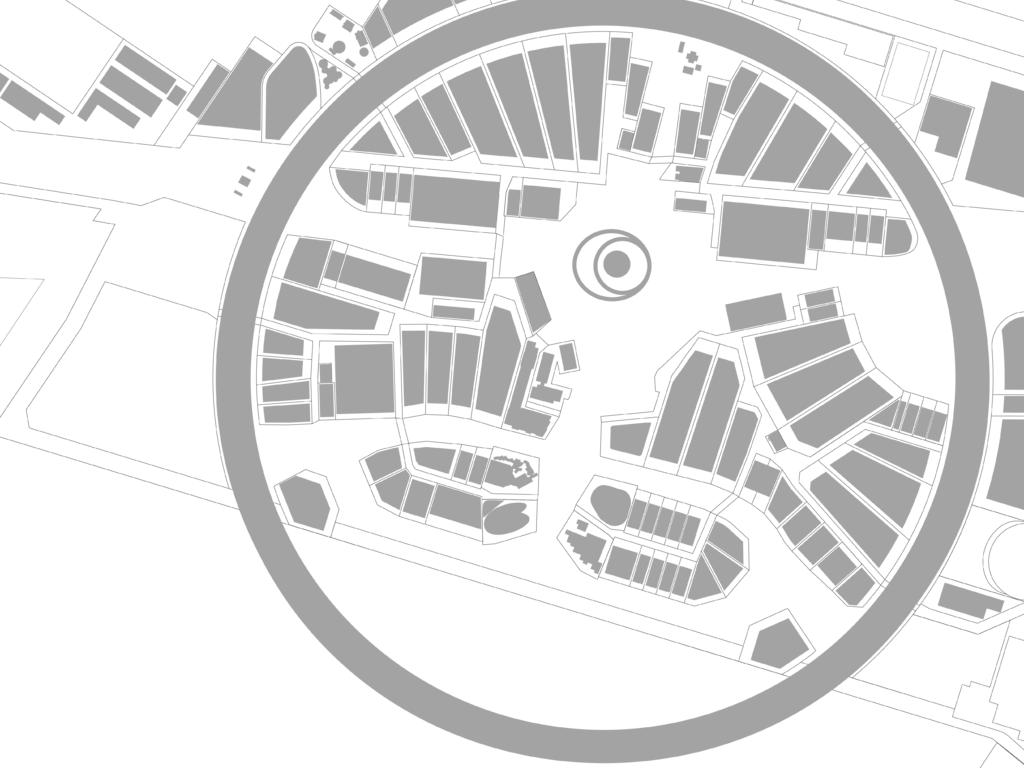

Located in the “Empowering Life” zone of the expo, the Swiss Pavilion offers 260 square meters of immersive and interactive experiences.

Embark on a captivating journey through the heart of Swiss innovation

At the Swiss Pavilion Want to host an event?

Whether you envision workshops, thematic conferences, networking events, demos, lectures, pitching sessions, or something else, we welcome your ideas! Activities can be public or private, specialized or more general, small or large-scale. They can be held in the Swiss Pavilion’s event space, partner locations like the Swissnex in Japan event & exhibition space in downtown Osaka, or even the Swiss Embassy in Tokyo.

Can’t make it to the Expo?

Virtual tour

Partners

Switzerland’s global image is closely associated with the reputation of Swiss companies in numerous sectors. The Swiss Pavilion is an ideal communication platform for those who want to partner with the Swiss government and showcase their activities abroad.

Want to join us in showcasing Swiss innovation at Expo 2025 in Osaka? Together, we can create a remarkable experience that inspires and connects with audiences from around the world.

Get in Touch

Can’t find what you are looking for? You can contact us by email or try the FAQ below.

For Media/Press inquiries

Béatrice Bleuler

Communication Manager, Swiss Pavilion Expo 2025 Osaka Kansai, Presence Switzerland

FAQ

With its theme “Designing Future Societies for our Lives,” Expo 2025 will become a key platform for reaching the SDGs by 2030. It is also intended to drive co-creation by the international community in designing a sustainable society that supports individuals’ ideas of how they want to live.

Switzerland will showcase excellence in innovation and creativity through three major themes shaping the exhibition and event program: Augmented Human, Life, and Planet. The pavilion will serve as a significant platform to position Switzerland as an innovative and reliable partner, extending a hand to tackle major global challenges alongside other nations.

The themes “Augmented Human,” “Life,” and “Planet” were chosen based on a survey conducted in both Japan and Switzerland. This survey, which involved public and private stakeholders, examined a wide range of topics where Switzerland excels and which are highly relevant to the Japanese audience. From these results, the three most compelling themes were identified and subsequently approved by parliament.

The anime “Heidi, Girl of the Alps” is a beloved icon in Japan. As a well-known character, Heidi will be a key ambassador for our pavilion, featured prominently throughout the visitor experience. From the entrance to the Heidi Café, visitors will have multiple opportunities to explore the history of this Swiss character and her enduring impact on Switzerland’s image.

As the Expo is a platform for sharing expertise on a sustainable future, our aim is to contribute to this dynamic by building a pavilion with the lowest possible environmental impact. Thanks in particular to a very light material for the spheres, the pavilion’s membrane weighs around 450kg – just 1% of a conventional building shell. “Our exhibition structure for Osaka will be the lightest ever built by Switzerland for a World Expo,” says General Commissioner Manuel Salchli.

The specific innovations are currently being selected. Please find below some subjects that will be highlighted:

AUGMENTED HUMAN Exhibition: 13.04-10.06.2025

Robotics, AI, Quantum, Augmented Reality, Virtual Reality, Collective Intelligence, Digital Security, Consciousness Augmentation, Space

LIFE Exhibition: 11.06-12.08.2025

Health Span Extension, Human Applications of genetic Engineering, Infectious Diseases, Science Diplomacy, Future of Education, Future of Economics, Trade and globalisation, Synthetic Biology, Organoids, Art & Science

PLANET Exhibition: 13.08-13.10.2025

Greetech, Decarbonisation, Earth Systems Modelling, Future Food Systems, Space Resources, Ocean Stewardship, Solar Radiation Modification, Eco-augmentation

Switzerland and Japan’s strong ties are also displayed in Heidi Café’s menu. Enjoy our selection of Swiss dishes infused with Japanese flavors: Osaka Swiss hot dog with seaweed and wasabi mayonnaise, raclette and charcuterie and Swiss cheese platter. For dessert, carrot cheese cake, chocolate drink, and various mousses.

We serve premium Swiss wines from our partner Swiss Wine Promotion, beers, cocktails, and mocktails carefully curated to complement the flavors of our dishes.

Thank you for your interest in joining our team! At this time, we do not have any job openings available. If we have a vacancy, we will publish it on this website. So we encourage you to check back regularly. We appreciate your understanding and wish you the best in your job search.

Swissnex will maintain an active presence outside the expo site through a satellite location in the city. During the expo, we will be hosting various events and exhibitions throughout its entire duration. We invite you to visit the Calendar section of our website to explore a selection of upcoming events.